3 Ways CAD/CAM Can Reduce Costs in Your Surfboard Business

The goal of this blog post is to help you better understand how CAD/CAM software can be utilised in the various departments of your business to reduce costs.

[CAD/CAM stands for Computer-Aided Design/Computer-Aided Manufacturing. It is a software program that combines computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. CAD software is used to create 2D or 3D models of products, while CAM software is used to generate the instructions that control machine tools in the manufacturing process.]

Manufacturing surfboards is a revolving door of processing orders, ordering materials, manufacturing, and maintaining a strong balance sheet to keep the business operating. Oftentimes, surfboard manufacturing has variable costs due to seasonal fluctuations and custom orders. By leaning on resources like CAD/CAM, your business can utilise tools that will help you better organise, process orders faster, and reduce variable costs. Below, we discuss three ways CAD/CAM can be utilised to reduce costs in your business.

#1 Rapid design and prototyping:

CAD software can be used to create detailed 3D models of surfboards, which can then be used to test different designs and shapes. This can help surfboard manufacturers quickly refine shapes, ultimately leading to reduced costs. For example, CAD/CAM software can be used to test rocker profiles and rail shapes to see how they affect the performance of the surfboard. This information can then be used to refine the design of the surfboard, resulting in a better-performing board that can be manufactured more efficiently.

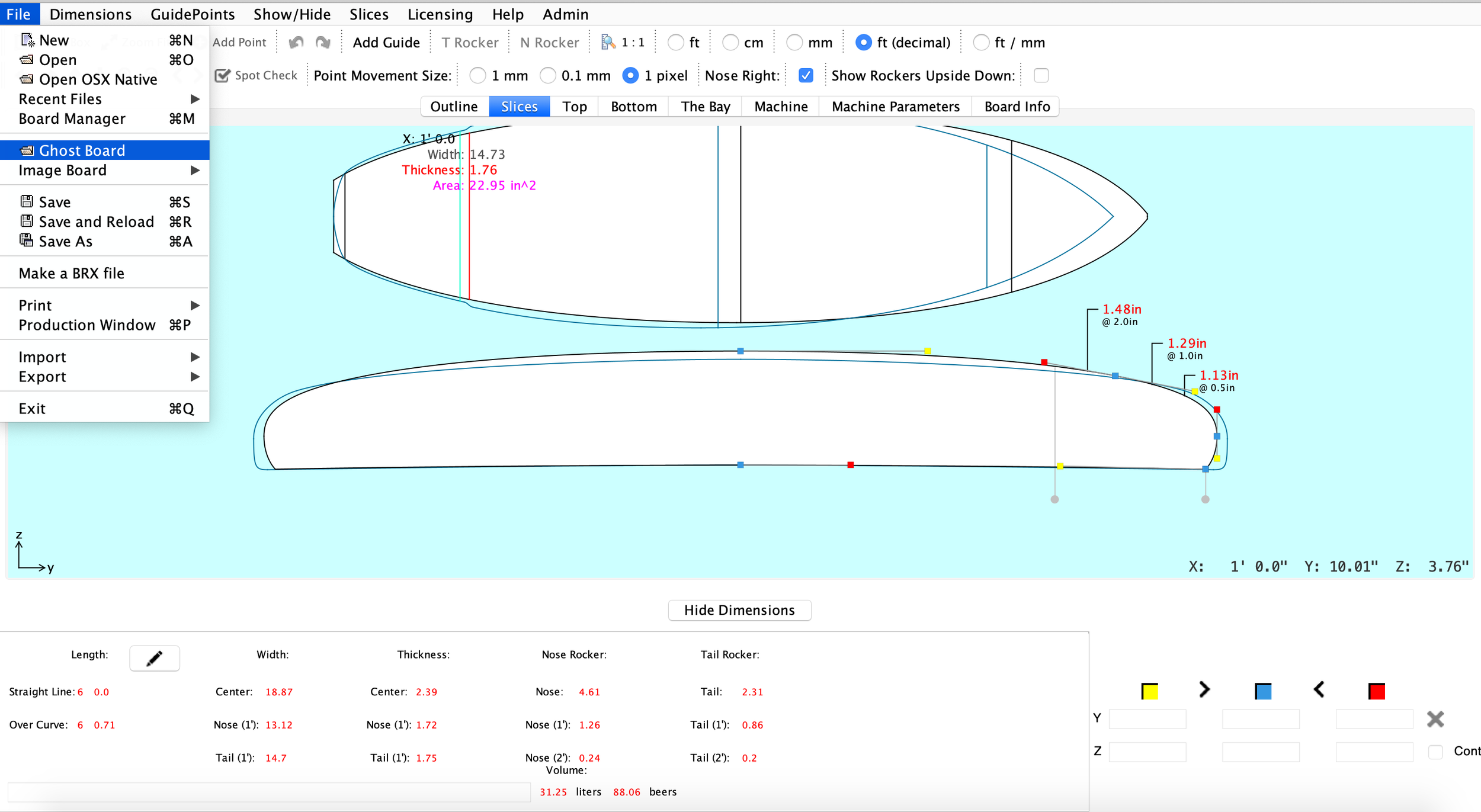

Tools in AkuShaper, like the Ghost Board function, can speed up design improvements by digitally overlaying two boards at once to make quick changes to the board based on customer feedback, shaper knowledge, and the original design of the board.

Ghost Board Function: Overlay of two board designs

#2 Automated manufacturing:

CAD/CAM software can be used to automate parts of the manufacturing process of surfboards. This can help to reduce the amount of labour required to manufacture surfboards, which can lead to lower costs. Utilising automation tools that help take care of the boring/easy/dull work will allow you and your workers to focus on activities that add more value to the business. By eliminating the highly time consuming aspects of shaping surfboards, a business can significantly reduce their labour costs and focus on revenue generating activities. This can help a business get more boards into production.

The use of 3D modelling tools in AkuShaper can help a business reduce costs by spending less time refining shapes by hand. Board designs can be saved and easily manipulated based on rider feedback and notes from the shaping bay, significantly reducing the costs [blanks, labour, and glassing] that go into surfboard R&D.

#3 Improved quality control:

CAD/CAM can be used to ensure the exact same product comes out the way it should. It can help remove the variability that creeps in when human hands are involved. This can be done by using the software to create digital inspection plans that can be used to check the dimensions and shape of surfboards before they are finished. This can help to ensure that all surfboards meet the required standards, which can help to reduce the number of defective boards that need to be repaired or scrapped.

Tools like the Board Manager and Board Information Page in AkuShaper can be used to date and assign shaping order cards, add glassing instructions, and assign specific details to how a board should be finished. This automated organisation tool in AkuShaper can reduce mistakes in the manufacturing process and save a business a great deal of money replacing or fixing board orders.

AkuShaper Board Info Card found in the Print Menu

Overall, CAD/CAM software can be a valuable tool for surfboard manufacturers wishing to reduce costs in their business. Some questions you may ask yourself when considering if a CAD/CAM program can help your business reduce costs are:

Do I have a way to quickly improve my designs based on rider feedback?

Are my customers satisfied with their order delivery times?

What is my process for replicating proven models?

Have I maximised the amount of surfboards I am able to shape in a given period of time?

Are my customers satisfied with the quality of their surfboards?

Are there too many mistakes being made in my manufacturing process?

Am I spending too much time in one department of the manufacturing process?

Are there bottlenecks slowing down my production times? I.e. Not ordering enough materials

Is there enough R&D going into my designs?

If any of these questions exist in your business, then a CAD/CAM program may be beneficial for you. If you are interested in learning more about how a CAD/CAM program like AkuShaper can help improve your business and reduce costs, please contact us or leave a comment below.