Get Started Using AkuShaper’s Industry Leading Surfboard Shaping Software

Free Demo

Try out all the design and visualization features.

You can also save your work while in Demo Mode and then unlock your saved designs after signing up.

Backyarder Plan

The basic plan that lets you design and save surfboards.

-

Open, edit, and save boards

Print Order Cards to send to friends/customers

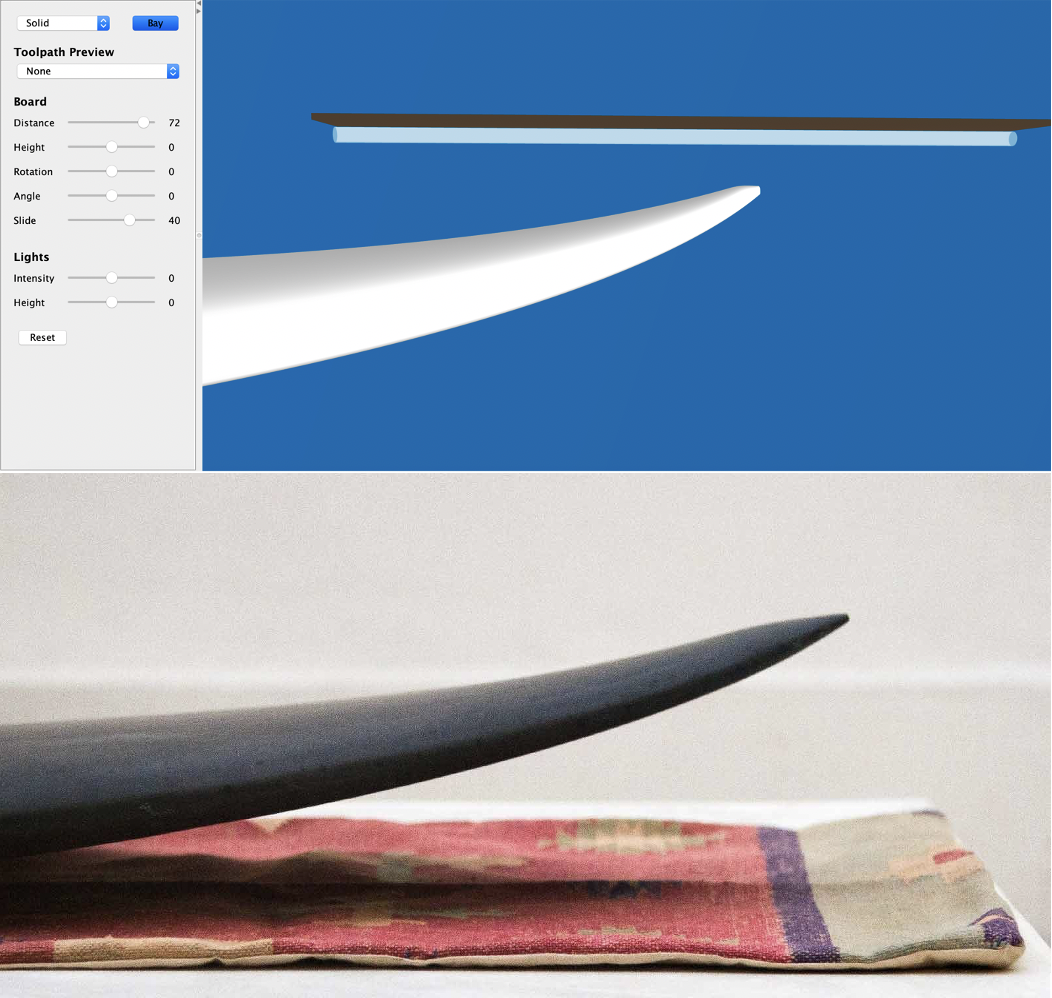

Look things over in the 3-D shaping bay™

Get CNC cuts from your local factory

Spot Check

Adjust colors of the Bay

Import/Export outlines, rails, and rockers for duplicating boards

Sliding Dimensions

Horizontal Line Guide

Open multiple boards

Export Shape3d format

Dimensions Adjustment Tool

Continuous Rail Tool

Tail Rocker & Nose Rocker Auto Adjusting

Add Control Points

Zoom Box

Undo/Redo

ft, cm, mm, ft/cm, ft/mm measurements

Show Rocker Upside Down

Nose right tool

Point Movement Size adjustments

Offline Activation

Keyboard Shortcuts

Slice real time display (continuous)

Up and Comer Plan

Powerful design, automation, and organization features.

-

Automated scaling / rocker adjustments tools to manage your growing collection of designs

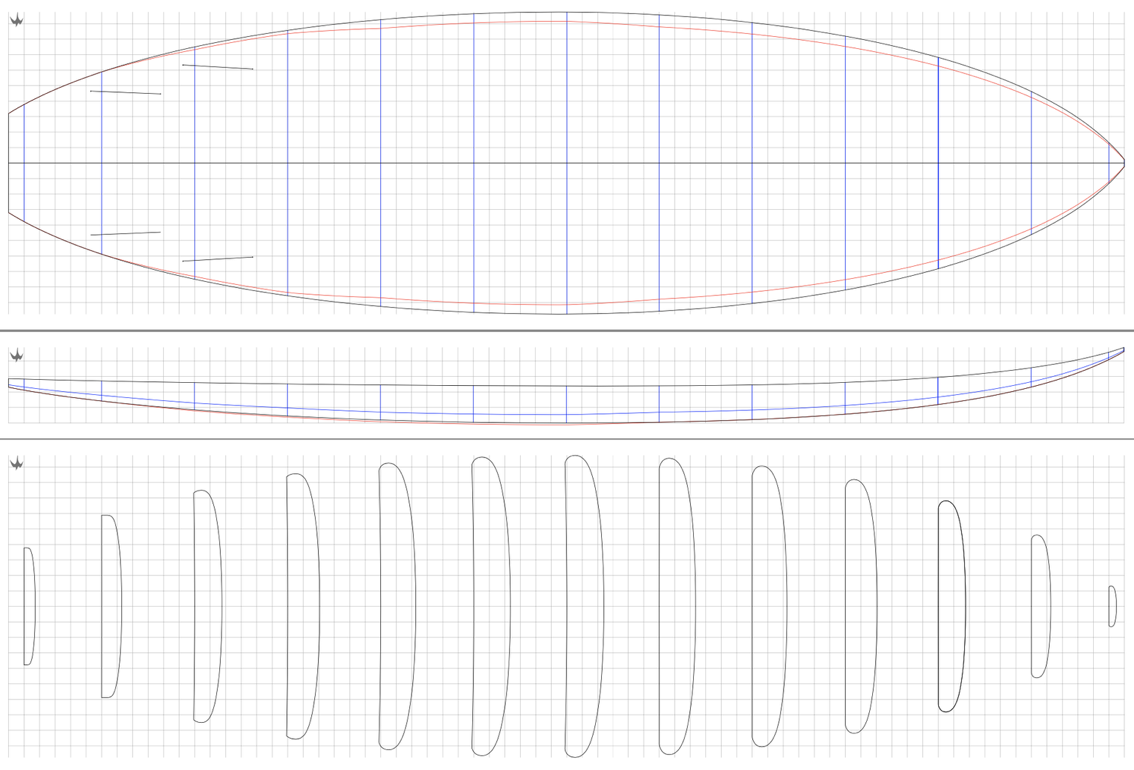

Print outlines, rockers and slices

Import boards from Shape3d (.s3dx) and DSD (.srf)

Visualize rail lines for better feedback on the smoothness of your rail curves

Expanded View stretches the outline/rocker to fill the screen for finer editing

Straight line vs. Over the Curve adjusting

Full size PDF Export Printing (Single sheet outline printing)

Rail Thickness Marks

Fin Marking Tools

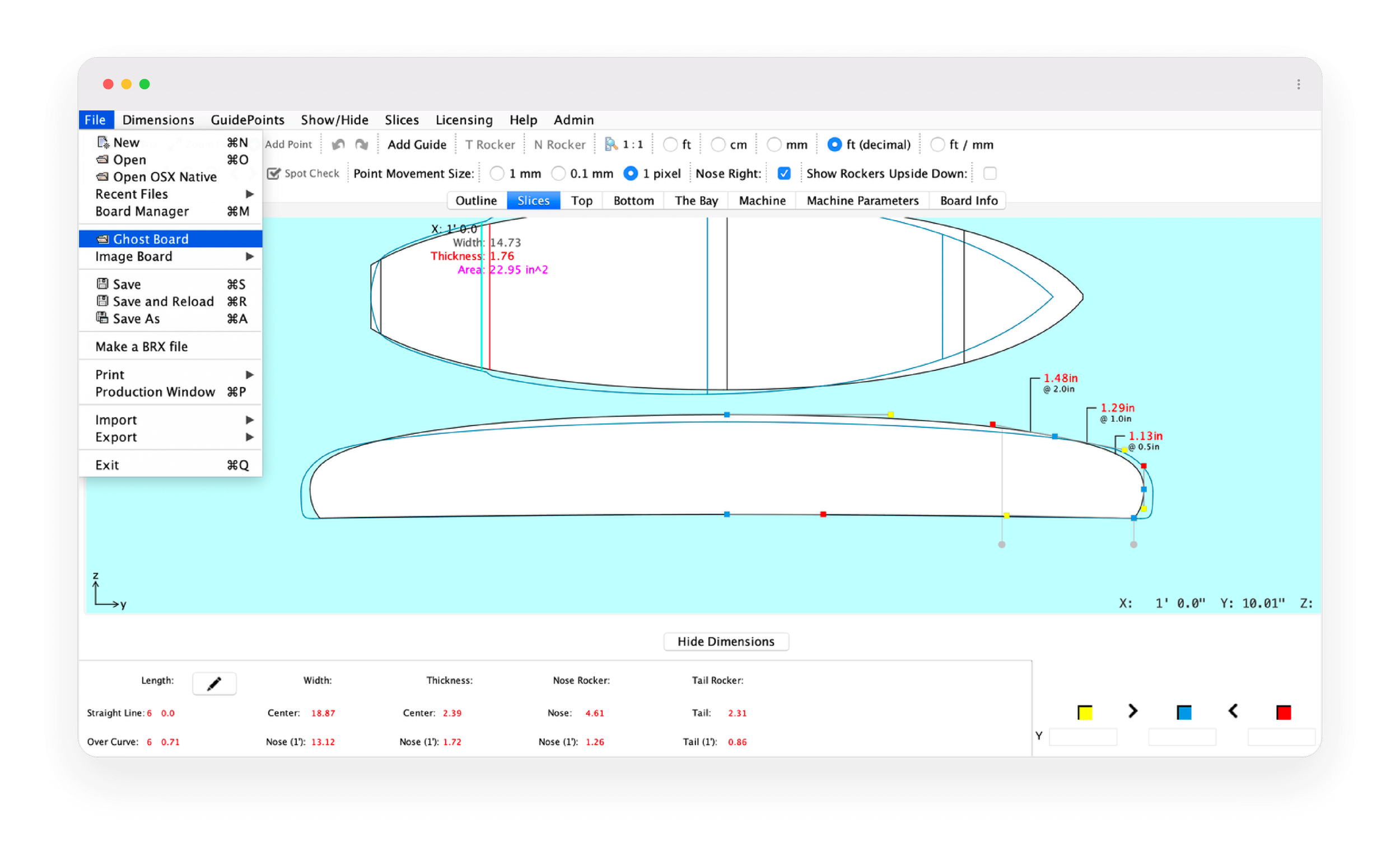

Ghost Board Overlay

Ghost Board Dimensions

Tokoro Rail Thickness

Guide Points Plotter

Draggable Board in Blank (Fit your designs with blank files)

Biolos Foot Marks

Image Board Function

Image Rails and Rockers

Board Manager

Slice Area Profile

Rail Tuck & Apex Display (editing ability in Heavyweight plan)

Volume Sections

Blank Differentials

Center of Mass Tool

Show Mass Area Line

Show Center of Mass

Hollow Board Plan Export

Heavyweight Plan

All the tools a professional shaper requires.

-

Includes all Backyarder and Up & Comer features**

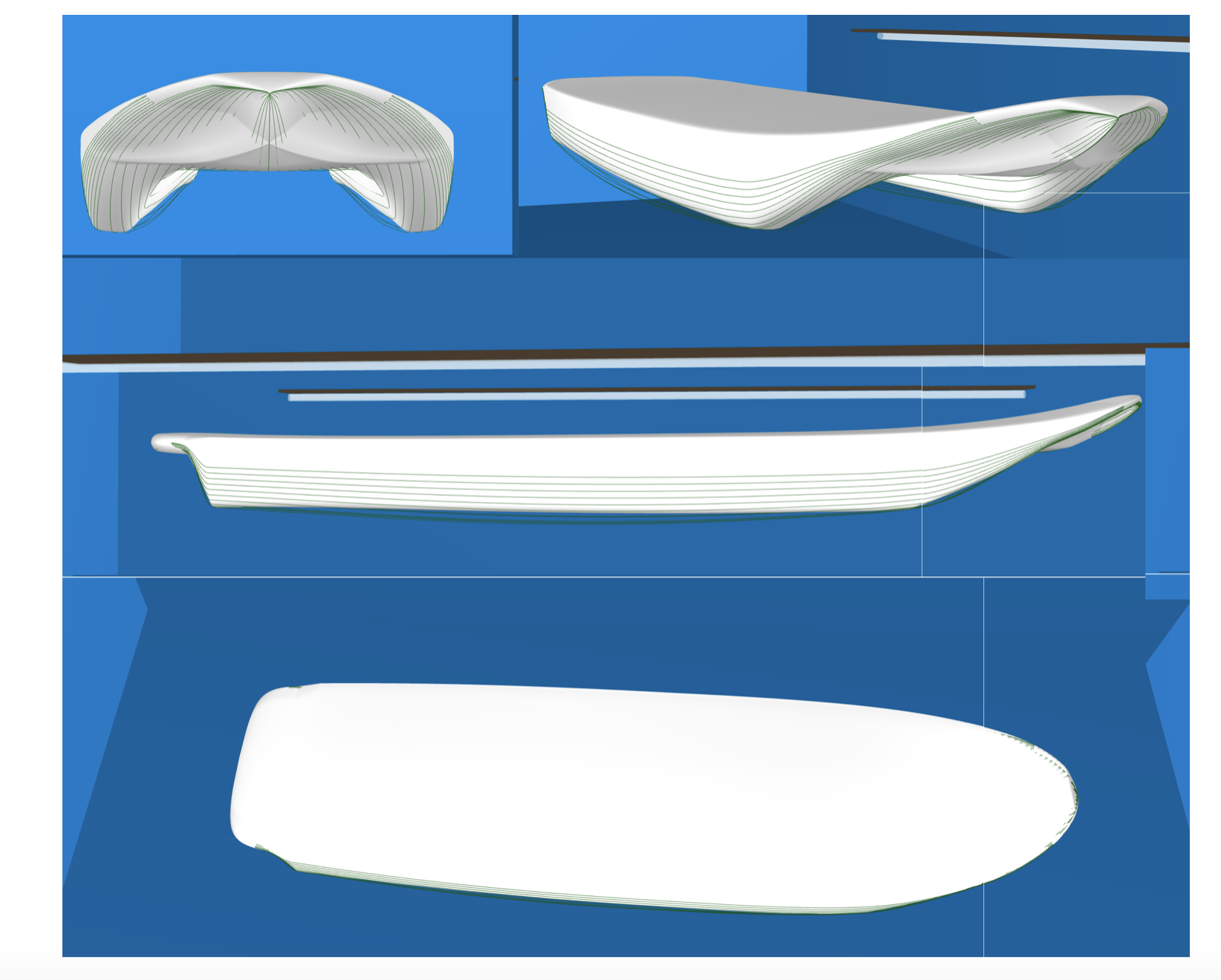

Export your 3D designs in OBJ, STL, IGES, and DXF file formats

Secure your designs with BRX™, our password protected file format

Preview cutting paths within AkuShaper software

Contour Highlight 3D view gives more insight into concaves and bottom contours

Automatically fit the board's curve to guidepoints

Rail Curve Refiner: Edit tuck and apex curves in Outline and Profile views

AkuShaper Can Help.

Focus on the board, not the complexity of the tool.

Expand Your Quiver with AkuShaper

Replicate your magic boards in a variety of sizes using our automatic scaling tools.

Streamline Your Surfboard Production

Fast, easy file generation for streamlined production. AkuShaper files are compatible with over 300 CNC machines worldwide.

24/7 Customer Support Provided

Our expert staff of surfboard design specialist are available to answer all of your questions

What Makes Our Software Different

Design from a Shaper's Perspective

Intuitive 2D layouts of the deck outline

Top and bottom look as a surfer would expect when inspecting his own board.

Every element of the design is customized through the use of bezier curves.

Fluid continuous lines controlled through 3 control points each that match exactly the contours of your board.

Why Thousands of Shapers Rely on AkuShaper

How Surfboard Shapers Use AkuShaper

Click an item below to jump to that section

- Hand Shaping with Accuracy

- CNC Cutting Surfboards

- Blank Fitting for Precision

- Printing Templates and Guides

- Hot-Wire Cutting Blanks

- Scaling Models into Full Size Ranges

- Live Design Consultations with Customers

- Sending the PDF Design Card for Approval

- Making Hollow Wood Surfboards

- Exporting for CAD, CAM & 3D Modeling

- Designing and Ordering Custom Blanks

- Collaborating with Glassing & CNC Shops

- Reducing Shaping Errors

- Managing a Library of Shapes

- Training Staff or Apprentices

- Marketing Your Designs Online

- Creating Experimental and Specialty Boards

- Systematic Approach in Prototyping

- Capture & Repeat Your Hand-Shaped Magic

1. Hand Shaping with Accuracy

Use printed outlines, rocker curves, and dimension guides directly in your bay to shape foam by hand with professional precision.

You can print full-size outlines, rocker curves, and dimension cross-sections directly from your digital design. Tape them to the shaping bay wall, trace them onto your blank, or use them as a reference during shaping to hit target dimensions with confidence.

Benefits:

More accuracy, less guesswork — match your digital design on the foam, line for line.

Custom shaping made easier — perfect for one-offs or highly specific customer requests.

Use as a teaching tool — ideal for shaping schools or apprentices learning the craft.

Maintain consistency across customs — especially helpful when shaping repeat orders by hand.

2. CNC Cutting Surfboards

Export your designs in BRD, DXF, IGES, STL, or OBJ for seamless CNC machine compatibility — either in-house or at a partner facility.

Find a full list of CNC locations here: https://akushaper.com/directory

Benefits:

Save time and labor — get from design to cut blank in minutes instead of hours

Consistent cuts every time — perfect for repeat orders, size runs, or production scaling

Reduce shaping errors — the machine executes your design with sub-millimeter accuracy

Free up your workflow — spend more time on design, detail work, and customer service

Work with global partners — easily send files to CNC-ready shops around the world

3. Blank Fitting for Precision

Use the Blank Fitting tab to match your design to the best-fitting foam blank — whether you're cutting by hand or with a CNC machine. Helps reduce waste and improves accuracy during shaping.

With a full library of manufacturer blanks available HERE, you can instantly overlay your board design onto a virtual blank to check rocker compatibility, outline fit, thickness flow, and stringer alignment. This ensures your design fits cleanly within the blank — whether you’re shaping by hand or exporting to CNC.

Benefits:

Avoid costly mistakes — don’t discover a poor fit halfway through the cut.

Reduce waste — select a blank that requires minimal planing and foam removal.

Save time in the bay — the closer the fit, the less shaping and fine-tuning required.

Order smarter — confidently choose blanks based on precise rocker and volume needs.

Visual confidence — see exactly how your shape sits inside the foam before making a decision.

“Blank fitting used to be a guessing game. Now I check the AkuShaper fit, order with confidence, and spend less time shaping down excess foam.”

— Rob L., Production Shaper in South Africa

4. Printing Templates and Guides

Save, duplicate, and refine all your past and current models. Perfect for repeat customers, product lineups, or making quick adjustments. From outlines and rocker profiles to thickness flow and cross-sections, every curve in your digital design can be turned into a printable reference. These can be taped to your bay wall, traced directly onto foam, or transferred to template board to cut reusable jigs.

What you can print:

Outline templates for accurate side cuts

Rocker curves to guide bottom shaping

Cross-sections and rail profiles to dial in foil and feel

Thickness and volume charts to keep shapes consistent

Measurement overlays for detailed spec tracking

5. Hot-Wire Cutting Blanks

Fit your board to a specific blank, then export precise rocker and outline cuts for hot-wire blank cutting.

Once your board is matched to a blank using the Blank Fitting tool, you can export accurate rocker and outline profiles that are ready for hot-wire machines or manual cutting setups.

These profiles give you a clean starting point that closely follows your digital design, reducing the amount of foam you need to remove later and saving time in the bay or on the CNC table.

How it works:

Fit your design to a commercial blank using the Blank Fitting tab

Export the rocker profile and outline profile as DXF or printable templates

Load those files into a hot-wire cutting rig (or trace them onto a cutting jig)

Cut the blank to shape with speed and confidence

Learn more about hot-wiring your own blanks here: https://akushaper.com/articles/how-to-hot-wire-your-own-blanks

6. Scaling Models into Full Size Ranges

One design can be easily scaled up or down, giving you a lineup of the same model in multiple lengths and volumes — perfect for production runs or web stores.

You can scale your model up or down while preserving the original shape’s proportions, curves, and performance characteristics.

This makes it easy to create a full product line — from 5'8" to 6'8" (or beyond) — that looks, feels, and performs like a cohesive family of boards. Whether you're selling direct to customers, stocking a surf shop, or offering online orders, scalable models give you a professional, complete lineup.

Why it matters:

Maintain design integrity across sizes — rocker, rails, and foil flow scale proportionally

Meet more customer needs — different lengths and volumes for different riders and conditions

Speed up model development — make one shape great, then expand it in minutes

Look professional online — offer a full size range on your site or catalog without extra design time

Perfect for wholesale or surf shop accounts — shops love seeing full size runs in one model family

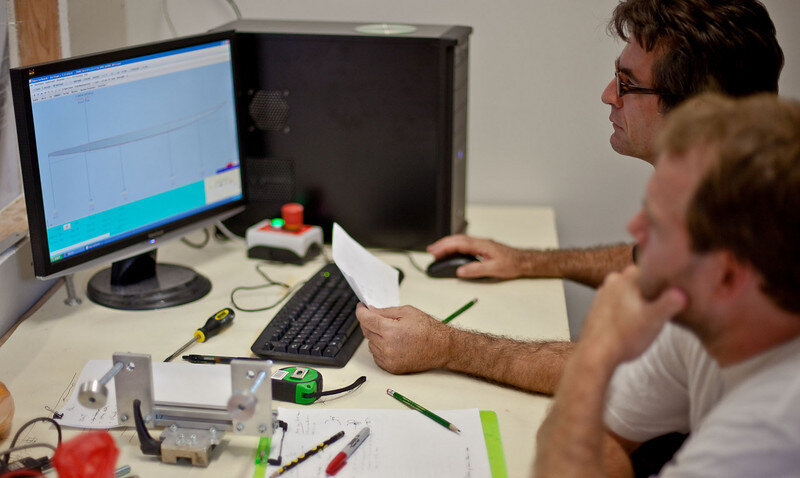

7. Live Design Consultations with Customers

Use AkuShaper like a digital whiteboard — tweak a board live in front of a customer, adjust dims, and lock in their perfect custom shape.

AkuShaper turns your custom board process into an interactive, professional experience. Whether you're meeting in person or over video, you can open a board design, make real-time adjustments, and visually walk the customer through their shape — just like a digital whiteboard.

Tweak the outline, rocker, dimensions, rails, or volume while they watch, and lock in exactly what they’re looking for. Seeing their input reflected instantly builds trust, eliminates miscommunication, and speeds up approvals.

Why it works:

Boosts customer confidence — they see the shape being built and feel part of the process

Faster sign-offs — with real-time visualization, you avoid endless back-and-forth emails

Upsells are easier — when customers understand their options, they’re more likely to commit to premium features or second boards

Great for remote orders — collaborate with customers anywhere in the world via screen share or Zoom

Stand out as a pro — most shapers don’t offer this level of digital service

“I used to email screenshots back and forth. Now I just hop on a Zoom call, tweak the rocker or dims in front of the customer, and finalize the order in one sitting.”

— Evan R., Custom Board Builder in the Pacific Northwest

8. Sending the PDF Design Card for Approval

Generate a branded, professional PDF order summary to email to customers. Speeds up approval, reduces miscommunication.

You can email this directly to your customer for final approval before cutting foam or shaping by hand. It acts as a visual contract, ensuring everyone is on the same page and reducing back-and-forth messages or costly misunderstandings.

Why it’s powerful:

Saves time — customers can approve designs quickly, even from their phone

Reduces mistakes — design details are clearly documented before any work begins

Builds trust — customers feel like they’re working with a professional, not guessing at what they’re getting

Looks clean and branded — ideal for custom orders, wholesale, or retail buyers

Creates a paper trail — helpful for customer records, revisions, or reorders down the line

“I send the PDF Design Card as soon as we finalize a shape — customers love seeing the specs laid out professionally, and I get faster sign-offs.”

— Lisa T., Custom Board Shaper in Australia

9. Making Hollow Wood Surfboards

Design your board digitally, then export for full-size printing or CAD to build hollow frame templates (e.g., with the HBTM tool), perfect for eco-conscious wooden builds.

Workflow example:

Design your board in AkuShaper

Use HBTM to generate the rib frame system

Export templates as PDF or DXF

Cut frames using laser, CNC, or print-and-trace

Assemble, skin, and finish your board in wood

10. Exporting for CAD, CAM & 3D Modeling

AkuShaper isn’t just for surfboard design — it’s a powerful launch point for advanced workflows across CAD, CAM, and 3D modeling environments. Once your board is designed, you can export it in professional-grade formats such as IGES, STL, DXF, or OBJ — giving you full compatibility with a wide range of digital tools used in manufacturing, simulation, and visualization.

Why it matters:

Plug into industry-standard software — export IGES or STL for Rhino, SolidWorks, Fusion 360, or similar tools

Simulate before you build — analyze rocker lines, volume flow, or drag using fluid dynamics software

Design custom tooling — create precise molds for vacuum forming, thermoforming, or composite layups

Create high-end 3D renders — use OBJ or STL for photorealistic marketing visuals

Support hybrid manufacturing — combine surfboard designs with other product workflows (like soft tops, wakeboards, snowboards, etc.)

11. Designing and Ordering Custom Blanks

When off-the-shelf blanks don’t quite fit your vision — or your rocker, foil, or outline needs something unique — AkuShaper makes it easy to design and order custom blanks with precision and repeatability.

Why it’s valuable:

Build blanks around your best shapes — not the other way around

Perfect for niche designs — guns, mids, or retro boards with unusual rockers or outlines

Match team rider specs — fine-tune blank curves for elite performance

Use as a production tool — make repeatable blanks for shaping schools or factory settings

Simplify sourcing — send exact files to blank suppliers with zero ambiguity

12. Collaborating with Glassing & CNC Shops

Once your designs are dialed, AkuShaper helps you streamline your workflow with CNC cutting facilities and glassing shops — so you can spend less time managing orders and more time growing your business.

Every board you shape in AkuShaper becomes a repeatable CAD file, ready to send directly to production partners. Whether you're working with a local CNC machine or a national/international glassing facility, having clean digital files reduces miscommunication, speeds up turnaround, and creates consistency across your product line.

Once you’ve built a trusted workflow with a factory or glass shop, you can get into a rhythm: design, export, cut, glass, repeat. That means faster deliveries, fewer errors, and a clear path to scaling your board business — regionally or globally.

Why it matters:

Faster turnaround times — send CAD-ready files straight to your factory

Fewer back-and-forths — clean digital specs reduce questions and confusion

Repeatable results — perfect for batch orders, surf shop lines, or online stores

Scale with confidence — produce boards anywhere in the world using your digital catalog

Stay organized — all designs are saved, searchable, and editable for future production

13. Reducing Shaping Errors

From rocker curves to width, thickness flow, and volume, AkuShaper keeps your numbers consistent from screen to foam. Whether you're shaping by hand using printed templates or exporting to CNC, you’re working from a single source of truth — not guesswork.

It’s especially valuable for custom boards and repeat orders, where precision matters and even small errors can lead to customer dissatisfaction or lost materials.

Why it matters:

Stay consistent across builds — no more second-guessing old measurements or trying to replicate from memory

Better customer experience — your custom boards match the specs they signed off on

Improve factory reliability — CNC shops and glassing partners work from precise, standardized files

Reduce material waste — fewer re-shapes, misfits, or rejected blanks

Saves time — eliminate the need for mid-build adjustments or “fixes” during sanding or glassing

14. Managing a Library of Shapes

Every time you design a board in AkuShaper, it becomes part of your personal, searchable digital library — complete with outline, rocker, dimensions, volume, fin setup, and notes. You can save, duplicate, refine, and reference any shape, whether it’s a brand-new model, a customer’s custom board, or a high-performing design you want to scale.

This library becomes your go-to archive for everything from quick customer reorders to surf shop production runs. As your design catalog grows, you’ll gain better version control, clearer records, and the ability to move faster on everything from prototyping to production.

Why it matters:

Never start from scratch again — duplicate a proven design and tweak it for new waves, riders, or materials

Faster reorders — instantly pull up past customer boards, adjust dims, and hit print or export

Version control — refine your best shapes over time and track what changes made the difference

Build a product line — organize your catalog by board type, length, or model family

Better for teams — multiple shapers or production staff can reference the same files for consistency

Future-proof your work — your best ideas won’t get lost in the notebook or on a forgotten template

Use the Board Manager and PDF Order Cards to streamline your production workflow and keep everything organized.

15. Training Staff or Apprentices

As your shaping business grows, consistency becomes critical — and that means having tools in place to train others without sacrificing quality. With AkuShaper, your saved board files and printable templates become a built-in training system for junior shapers, machine operators, and apprentices.

Instead of relying on verbal instructions or hand-drawn templates, you can give your team exact dimensions, outlines, rocker curves, and cross-sections to follow — all generated directly from your digital designs. This ensures that even as you delegate more of the shaping process, your boards retain the curves, feel, and performance you're known for.

Why it matters:

Maintain quality control — every team member works from the same specs and references

Accelerate learning curves — new shapers can visualize curves and study cross-sections before ever picking up a planer

Support both hand shaping and CNC workflows — useful whether you're training on the tools or in front of the machine

Build a scalable operation — standardize the way you teach, review, and sign off on boards

Create teaching materials — use AkuShaper screenshots, PDFs, and templates in your SOPs or employee manuals

16. Marketing Your Designs Online

AkuShaper makes it easy to turn your digital board files into high-quality visuals and web-ready content that help your customers understand (and get excited about) what you're offering.

With just a few clicks, you can capture clean screenshots, export 3D files, or generate PDF design cards to showcase your models on your website, social media, or online store. This lets customers preview outlines, volumes, rockers, and dimensions — and makes it easier for them to pick the right board before reaching out.

Upload your AkuShaper designs in Pocket Quiver: https://pocketquiver.com

Why it works:

Increases online conversions — shoppers are more likely to buy when they understand what they’re looking at

Builds brand trust — pro-level visuals reflect a pro-level shaping process

Reduces pre-sale questions — design specs are visible upfront

Improves search visibility — clean product pages with specs help with SEO

Ideal for surf shops and distributors — easy to share your lineup digitally

17. Creating Experimental and Specialty Boards

AkuShaper allows for endless experimentation — from retro twin fins to displacement hulls to modern asymmetricals — all while keeping dimensions clean and repeatable.

Whether you're chasing niche performance characteristics or just having fun with unconventional ideas, AkuShaper gives you the tools to push boundaries without losing control.

You can:

Create a baseline model and quickly generate variations to compare

Adjust and mirror designs with the Ghost Board tools

Keep digital records of every experimental board — even one-offs

Share files with collaborators or CNC machines for accurate reproduction

Use the rocker and volume tools to check rideability before building

18. Systematic Approach in Prototyping

Great design is built on iteration — and AkuShaper gives you a clean, systematic way to test and improve your shapes over time.

With all your models stored digitally, you can create controlled variations: adjust just one element — like tail width, rocker, or rail shape — while keeping everything else identical. This lets you do true apples-to-apples comparisons, and helps isolate what really makes a board perform differently.

Why it matters:

Remove the guesswork — you’ll know exactly which design change caused a performance shift.

Build your own performance database over time by saving and labeling each variation.

Create a design tree — easily explore “branches” of your original model, with each new version representing one variable tweak.

Whether you're tuning a step-up, testing tail designs, or refining a best-seller, AkuShaper gives you a scientific approach to shaping — helping you evolve faster and design with confidence.

“With AkuShaper I can test ideas systematically. One board has a flatter entry rocker, one doesn’t — I surf both, and now I know. It’s like A/B testing for board design.”

— Diego M., Custom Shaper & Team Rider Coach

19. Capture & Repeat Your Hand-Shaped Magic

Lock in every curve, contour, and measurement from your best boards — down to the finest increment. AkuShaper makes it easy to digitize your hand-shaped magic so you can reproduce it later with precision.

Use the Board Info tab to input and save exact dimensions, rocker profiles, and outline points. Whether it’s a one-off custom or a board that just worked, you can bring it back anytime — perfectly matched.

Perfect for:

Saving your favorite hand shapes

Building a digital archive of proven designs

Reproducing “magic” boards for customers or team riders

Ready to try these tools for yourself?

Start your subscription today and see how AkuShaper fits into your shaping workflow.

“It is the most important design tool in our business.”

“We use AkuShaper to design every board we build.

The interactive tools in the software allow us to align our knowledge of surfboard functionality with the surfer’s vision for their board by bringing the design to life in real time. It is the most important design tool in our business.”

-Nick Halleran, Owner, Make and Ride Surf Exchange