17 Ways AkuShaper Can Make Your Surfboard Business More Profitable

If you shape surfboards for a living — or even as a serious side hustle — AkuShaper can pay for itself faster than you might think.

Here are 17 ways AkuShaper helps surfboard shapers turn design into dollars:

1. Sell Faster with Visuals & Customer PDFs

Use the Design Card export to send clean, clear PDFs of your board designs. Customers can see exactly what they’re getting — which helps close the sale.

Here's how it helps close the sale:

Reduces hesitation: Many customers hesitate to commit when they can’t clearly picture the final product. A clean design card eliminates that uncertainty.

Adds a premium touch: Providing a detailed spec sheet positions you as a pro — and adds perceived value to your board.

Simplifies approvals: When the customer signs off on the design card, you both have a clear record of what's being built — which prevents miscommunications later.

Works as a sales tool: If a customer is still shopping around, your design card gives them something to compare — and makes your process stand out.

2. Order the Right Blank Every Time

Avoid one of the most common — and costly — mistakes in surfboard production: ordering the wrong blank.

AkuShaper’s Blank Fitting tool lets you digitally match your design to real-world blanks from all major suppliers. Slide your board outline and rocker into the blank profile on screen to see if it fits — before you ever place an order.

Access hundreds of blank files in the AkuShaper Blank Library: https://www.akushaper.com/blanks

Why it matters:

Save time and money by avoiding blanks that are too short, too flat, or require excessive shaping.

Reduce foam waste by finding a blank that’s as close as possible to your design — less material cut away = more efficiency.

Place more confident orders — especially helpful if you're ordering blanks in bulk or working with overseas suppliers.

Speed up your shaping process — a good blank fit means less time planing down foam and more time dialing in details.

Whether you're cutting by hand or CNC, starting with the right blank is the foundation of a faster, more profitable build.

“The blank-fitting tool alone pays for my subscription. It’s saved me from ordering the wrong foam more than once — and that stuff’s not cheap.”

— Clint R., Small-Batch Shaper in North Carolina

3. Scale Models Across Sizes Instantly

Create a full size run of a board — or fine-tune dimensions for different wave conditions or rider preferences — in just a few clicks. With AkuShaper, you can modify key dimensions like rocker, width, and thickness incrementally, without redrawing the board from scratch.

Use the Board Info tab to adjust your rocker line numerically — a single value change updates the curve across the board, maintaining flow and proportion. You can also use the “auto adjust slices & rocker” tool to proportionally scale different dimensions across all models.

Perfect for:

Adapting a model for different rider weights

Creating step-up or groveler variants

Building consistent size ranges for production or retail

It’s fast, flexible, and ensures that every version of your board stays true to the original design.

4. Systematic Approach in Prototyping

Great design is built on iteration — and AkuShaper gives you a clean, systematic way to test and improve your shapes over time.

With all your models stored digitally, you can create controlled variations: adjust just one element — like tail width, rocker, or rail shape — while keeping everything else identical. This lets you do true apples-to-apples comparisons, and helps isolate what really makes a board perform differently.

Why it matters:

Remove the guesswork — you’ll know exactly which design change caused a performance shift.

Build your own performance database over time by saving and labeling each variation.

Create a design tree — easily explore “branches” of your original model, with each new version representing one variable tweak.

Whether you're tuning a step-up, testing tail designs, or refining a best-seller, AkuShaper gives you a scientific approach to shaping — helping you evolve faster and design with confidence.

“With AkuShaper I can test ideas systematically. One board has a flatter entry rocker, one doesn’t — I surf both, and now I know. It’s like A/B testing for board design.”

— Diego M., Custom Shaper & Team Rider Coach

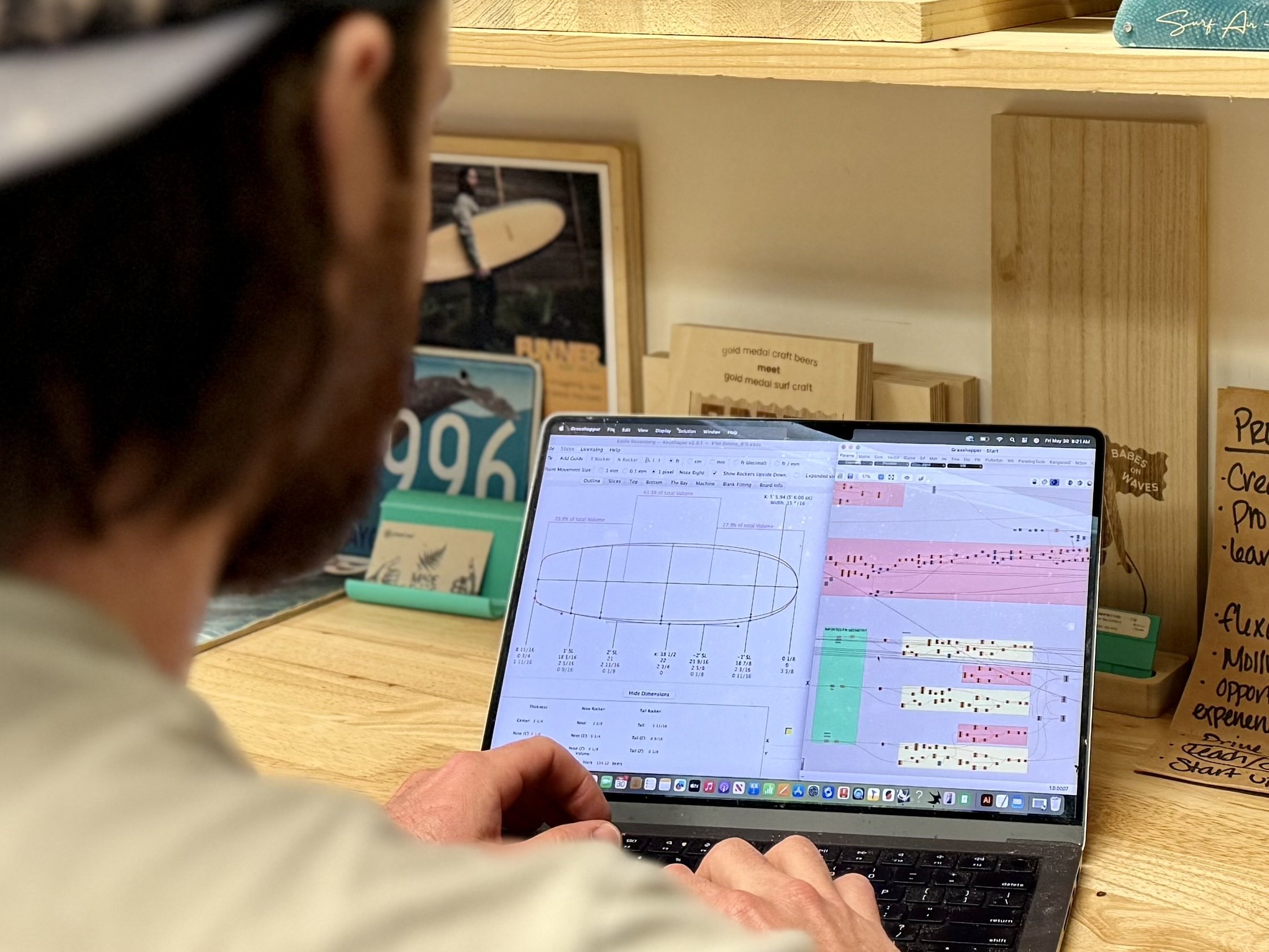

5. Real-Time Custom Board Consultations

Walk customers through design changes live, either in person or over video. They’ll feel included, and you’ll get faster sign-off on custom orders.

Why it works:

Builds trust quickly: Showing the customer their custom board comes to life on screen reassures them you’re listening — and capable of delivering.

Eliminates back-and-forth: Instead of weeks of email revisions, you get real-time signoff.

Creates a premium experience: Most shapers don’t offer this — which helps you stand out and command higher prices.

Great for remote orders: Whether you're shaping for someone across town or across the world, a screen share session can feel just as personal as meeting in person.

“I started using AkuShaper to walk customers through their custom boards on my laptop — and now it's a regular part of my sales process. They love seeing the board take shape and it speeds up approvals like crazy.”

— Jared B., Custom Shaper in California

6. Unlock CNC Cutting — Save Time & Labor

Send AkuShaper files straight to your CNC machine or a partner factory. That means faster builds, more boards per week, and more time spent refining, not roughing out.

Here's how it works:

Design Your Board in AkuShaper

Build your model with precise outline, rocker, thickness, and volume — exactly how you want it.Fit Your Design to a Blank

Use the built-in blank fitting tools to select a foam blank that closely matches your design. This reduces waste and ensures a better cut.Export CNC-Compatible Files

Choose your file format based on the machine or factory you’re working withSend to a CNC Machine or Factory

• If you own a CNC machine: Import the file into your cutting software and shape in-house.

• If you're outsourcing: Email the file to a local or global CNC cutting center (many are listed on AkuShaper’s industry directory).Pick Up or Receive Your Pre-Shaped Blank

The board arrives rough-cut to spec — just fine-tune rails, finish the shape, and you're ready to glass.

7. Build a Catalog of Sellable Shapes

Once you’ve nailed a design, you can scale it to a full size range with just a few clicks — perfect for retail orders or production runs. Each board you design in AkuShaper becomes a saved file, complete with volume, dims, and outline. Build a repeatable, searchable catalog of models. Keep your board models organized by using the “Board Manager” tool.

Key benefits:

Create size runs that maintain design integrity — from 5’8” to 6’8”, your board performs consistently at every length.

Speed up production workflows by reusing proven templates and exporting them instantly for CNC or print.

Build your own board catalog — organized, professional, and ready to share with customers, reps, or retail partners.

Use the “Board Manager” tool to sort, rename, and group your models by type, customer, board line, or series.

Easily track revisions and save multiple versions as you refine a shape or develop specialty variants.

8. Sell Boards Online with Clean Shape Renders

Your board designs shouldn’t stay trapped in your shaping bay. With AkuShaper, you can export clean shape visuals and use them across your website, online store, and social media — helping customers browse your models, compare outlines, and confidently choose the right board.

Use full-screen renders or simple outline views — whichever fits your brand. It’s a huge step up from blurry phone pics or hand sketches.

Even better:

Export to third-party design tools like Inkscape or Illustrator to add logos, artwork, dimensions, and branding.

Upload directly into Pocket Quiver to create a sleek online board catalog — with dimensions, model names, and visual comparisons.

Use these visuals to display your lineup professionally on your website, in emails, or in digital catalogs for retailers or customers.

“I use AkuShaper to generate the shape renders, then finish them in Illustrator with my logos and color zones. Looks super dialed on my website — customers love it.”

— Mick L., Boutique Shaper in France

9. Collaborate Smoothly with Factories or Shapers

Export designs and share them with collaborators, riders, or factories. Everyone sees the same specs — reducing back-and-forth and costly mistakes.

Why it matters:

Faster production turnaround when your factory or CNC shop gets exactly what they need, the first time.

Co-shaping made easy — share a design with another shaper to tweak, improve, or adapt without losing the original concept.

Great for remote teams — share files with a glasser across town or a CNC shop across the globe.

10. Offer Specialty Builds (e.g., Wood or Snow-Inspired Boards)

AkuShaper isn’t just for traditional PU or EPS surfboards — it’s a powerful tool for shaping outside the box. Whether you're building hollow wood boards, binding-free snow-style boards, or other custom hybrids, AkuShaper gives you the precision and flexibility to bring unique ideas to life.

You can export designs as full-size printable templates, or as 3D files (STL, IGES, DXF) for use in CNC machines or laser cutters — making it ideal for non-standard construction methods.

Use cases include:

Hollow wood surfboards — use the HBTM (Hollow Board Template Maker) tool to create internal rib/frame structures with clean, aligned contours.

Bindingless snow-style boards — adapt rocker lines, outlines, and rail profiles to suit snow riding dynamics.

Experimental hybrids — combine surf, skate, or snow elements into original designs using AkuShaper’s customizable curves.

Eco-conscious builds — design boards around alternative materials and precise waste-reduction strategies.

11. Speed Up Reorders with Saved Designs

Customer wants the same board again? Pull it up and press go. Repeat orders take minutes, not hours.

Benefits:

Repeat orders take minutes, not hours — just load the design, verify dims, and start shaping or exporting to CNC.

Build customer loyalty by delivering the same board again and again — no variation, no surprises.

Quickly update past boards — want to add ¼” to the nose or fine-tune the tail? Tweak just that one part and save it as a new version.

Perfect for team riders, repeat customers, and wholesale accounts who need consistent models delivered on schedule.

12. Cut Down on Material Waste

Foam isn’t cheap — and neither is your time. AkuShaper helps you get more out of every blank by combining smart design tools with precision blank fitting, so you’re not over-shaping or grinding away unnecessary foam.

Using the Blank Fitting Tool, you can choose the most appropriate blank for each design before you even place your order. That means less over-foam to remove and fewer mistakes that lead to toss-outs.

How it saves money:

Tighter blank fits = less foam to remove, which means faster shaping and reduced wear on tools.

Fewer miscuts or remakes due to better visualization of fit, volume, and rocker before cutting.

Less wasted resin, glass, and labor on boards that get scrapped or reshaped mid-process.

Optimized for CNC or hand shaping — either way, you start closer to your target shape.

13. Improve Turnaround Times

Faster approvals, automated cuts, and clean specs mean shorter timelines and quicker paydays.

How AkuShaper speeds things up:

Design approvals happen sooner with PDF design cards you can email for instant customer sign-off.

No redraws or rework — once the design is approved, it’s production-ready.

Export CNC-ready files instantly (.BRD, IGES, STL, DXF, OBJ), so you can go from idea to machine in minutes.

Clear specs reduce back-and-forth between shaper, customer, factory, and glasser.

More accurate blank fitting minimizes cutting, shaping, and sanding time.

“I used to spend hours going back and forth with customers. Now I send a design card and they approve it the same day. That shaves days off my turnaround.”

— Kevin L., Custom Shaper in the UK

14. Win Wholesale or Retail Accounts with Consistency

Retailers want scalable, consistent models. AkuShaper helps you deliver identical curves across size ranges — giving your boards a factory-level finish.

How AkuShaper helps you land accounts:

Repeatability at scale — every board off the CNC or shaped by hand from your template matches the master design.

Faster production — retailers want lead times you can hit. AkuShaper helps you get there.

Professional presentation — PDF specs, digital catalogs, and consistent design language make your brand retail-ready.

Easy size range expansion — scale your board model into a full range with consistent rail flow, volume, and rocker transitions.

Reduces returns or complaints — consistent boards = consistent stoke from surf shop customers.

15. Prototype Digitally Before Shaping Foam

Test outline tweaks, rocker changes, or volume shifts before you ever pick up a planer. That saves time and reduces throwaway prototypes.

Why digital prototyping makes sense:

Test rocker and outline changes visually and numerically — adjust key variables and immediately see the effects on volume, flow, and proportions.

Try radical or new ideas risk-free — experiment without wasting blanks or hours in the bay.

Build side-by-side comparisons to evaluate which version to move forward with.

Eliminate guesswork when refining a model — understand exactly how each change affects the board’s design.

Use design history to backtrack or branch off successful shapes (see also: Systematic Approach in Prototyping).

16. Attract More Customers with a Pro Workflow

Let customers see your process — renders, design consults, CAD-style PDFs — and they’ll know they’re working with a pro.

From digital renders and 3D models to branded PDF spec sheets and screen-shared design consults, AkuShaper turns your workflow into a professional customer experience that builds confidence and drives sales.

Why it brings in more customers:

Looks modern and organized — customers see that you use precision tools, not guesswork or napkin sketches.

Instills trust — customers know exactly what they're getting, and that you can reproduce it later.

Differentiates you from other shapers — especially in retail, online, or custom board markets.

Creates content — renders and PDFs double as promotional materials for your website, email, and social media.

Supports premium pricing — a dialed process feels high-end, and customers are often willing to pay more for that experience.

17. Increase the Perceived Value of Your Boards

Presenting a design card or walkthrough with every custom order makes your work feel premium. That adds real (and perceived) value to your product.

“It is the most important design tool in our business. We use AkuShaper to design every board we build. The interactive tools in the software allow us to align our knowledge of surfboard functionality with the surfer’s vision for their board by bringing the design to life in real time. It is the most important design tool in our business.”

-Nick Halleran, Owner, Make and Ride Surf Exchange

Bottom Line:

AkuShaper doesn’t just help you shape better — it helps you run a better business.

Whether you're hand-shaping in your backyard or running a full CNC-equipped factory, the right tools can turn time saved into money earned.

Still have questions? Reach out to us — we’d be happy to help you get more value from your subscription.