From Digital to Physical: Navigating the Backyarder Roadmap

We’ve all been there: staring at an AkuShaper file, obsessing over rail volume and entry rocker through ten different versions. But eventually, the screen goes dark, and the design stays in digital limbo. For many, indecision leads to inaction.

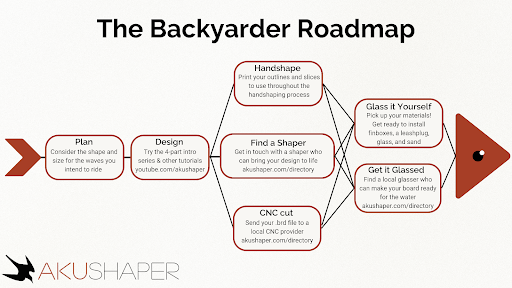

That’s why we created the Backyarder Roadmap. It’s the bridge between your digital file and your first wave.

From Screen to Machine

Tom is a hobbyist shaper who recently built an 8'4" longboard for his wife in his garage. He followed the following steps of the backyarder roadmap to get this board made:

Plan

Design

CNC Cut

Glass-it-yourself

Planning and Designing

These phases relied on a number of features included in the AkuShaper Backyarder plan such as image board modeling, and leveraging the file review service with an AkuShaper pro.

CNC Cut

Next up was connecting with a local CNC provider using the industry directory. That’s where Tom met Sean and the board started its trip into the real world. Seeing a pro-level CNC machine transform a digital file into a precise foam blank in minutes is a game-changer. It removes the "heavy mowing" to avoid more dust than some backyarders can handle at home.

Glass-it-yourself

No shapers bay? For a backyarder, shaping and/or glassing at home often requires getting creative. This build was no exception. Navigating resin fumes and neighborly etiquette, some creative cover in a new spot, using tools that aren’t always designed for the job. These things are all part of the process, but it’s the hard work that makes each wave that much more rewarding.

Ready to Start Your Roadmap?

If you’ve been sitting on a design for weeks, this is your sign to move. We’ve built the ecosystem—software, tech networks, and community support—to help you bridge the gap.

Stop designing. Start shaping. We’ll see you in the water.

Want to watch the full journey? Check out more real life shaper stories on our YouTube channel.